Stage 1: the 3 key actions before production begins

- Brands take careful steps at each stage of the production process to prevent defective products from reaching the consumer

- Choosing the right supplier, creating a “Golden Sample” and putting together a QC checklist before mass production begins are crucial steps to accomplish this

Purchasing a product that turns out to be defective is risky. While product defects are inevitable, reliable brands and manufacturers take careful steps to minimize quality errors in the final product.

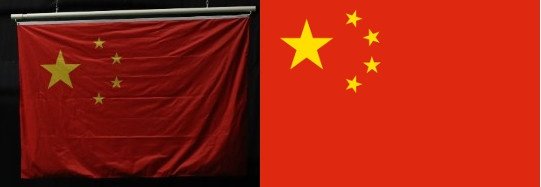

This is very important as even simple products can end up defective without stringent guidelines and quality checks. For instance, during the 2016 Olympic Games in Rio de Janeiro, two Chinese flags used during one medal ceremony did not conform to the official flag. The four small stars ran parallel to each other rather than rotated as in the official pattern. The mistake was so subtle that it could be easily missed if not paying careful attention: not only were officials at the Olympics unable to catch the issue, but the flags were made in China, and staff at the factory there overlooked the problem as well. Making product standards as clear as possible as well as choosing a reliable factory could greatly prevent such mistakes.

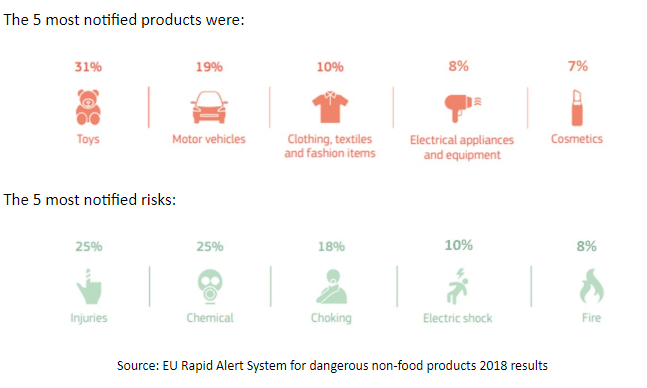

Being clear from the beginning not only ensures fewer product defects, but also allows for rigorous attention to product compliance. In 2018, 2,257 alerts regarding non-compliant products were sent through the Rapid Alert System in Europe alone.

Preventing product defects is done in 3 stages at different phases of the production process. In a series of articles, we will outline what these steps are to offer a look into how product quality is meticulously ensured.

The first stage is to prevent defects before production even begins. This is accomplished in 3 areas: choosing the right suppliers, establishing a product sample, and creating a quality checklist.

1. Choosing the right suppliers

Preventing product defects even before production begins starts with choosing the right supplier. The manufacturing process, the parts and materials used, and the factory staff all play a key role in determining the final quality of a product. Compromise in any one of these areas can undermine the whole process. Thus, choosing a supplier that provides quality service in all these aspects is crucial.

Competitive prices, quality results

Manufacturers always look into how to get the best price on their products. Responsible ones strive to find the middle ground, negotiating with suppliers to achieve this without comprcomplComising product quality. Brands and manufacturers want to produce at the best cost in order to offer products to you at competitive prices. However, lower prices increase the risk of producing lower quality products. Thus, they take the steps needed to ensure that the product is made from quality parts and materials at good rates.

Manufacturers first obtain price quotes from multiple suppliers to see what competitive suppliers are offering. This quote would also include a bill of materials (BoM) and an itemized list of pricing. This gives them a clear overview of the costs and quantities of parts and materials needed. From this they can make an informed decision about the best supplier for production.

Ideal Factory Conditions

The next step in picking the right supplier is auditing their factory. Gathering first-hand information about the factory where products will be made allows manufacturers to know first-hand whether the staff and equipment can produce high quality products under good conditions.

There are three main types of audits that can be performed. The first type is a social audit that is to assess factory conditions, worker treatment and compensation, hiring processes, and more generally, compliance with applicable laws.

The second main type of audit is an environmental audit, that is to assess the control the factory has on their release into water, soil, and air, as well as their energy consumption and management of chemicals. The audit would allow brands to see if factories match up to their own standards, as well as national and international ones.

The third type of audit is a technical audit. This audit would look into the technical aspects of production including the product development process, supplier management, the management of raw materials, storage management, equipment management and calibration, production control, and quality control. This audit would establish whether or not the factory has the proper means and systems to handle the brand’s requirements and quality standards.

In the current practice, the technical audit also involves a quality management system (QMS) audit. The whole audit setup is based on the ISO9001:2015 requirement plus individual product-specific requirements or customer concerned elements. So, the audit should be able to assess if the factory has valid quality procedures, standard, records and technical know-how in order to meet customer’s requirements and to ensure quality production.

The above audits are a general framework and factory inspections must be further adapted to the specific needs and requirements of the brand. For instance, if products are made with recycled materials, the QMS audit must assess whether the factory is able to provide clear traceability of materials, including specific controls or methods used during the production process.

Factories also need to be transparent with importers and inform them if any of the production process will be subcontracted. If a factory subcontracts work, the audits must be done with the subcontractor as well to ensure standards are consistent throughout the whole supply chain.

2. Establishing an approved product sample

After choosing the best supplier, the next step would be to establish an approved product sample.

A product will often go through multiple iterations before reaching its final form. At each stage, the product is checked to see whether it reaches the standards needed by the brand, retailer, or importer. This means checking the color, dimensions, materials and whether the product can function well. Often times, product samples are also sent to third-party certified labs to test certain attributes of their product. These tests are first to ensure that the products comply with destination market regulations. For example, toys are subjected to more than twenty tests. Toys are assessed to ensure that they will not break into small pieces that can be swallowed and become a choking hazard if fallen, crashed, torn or torqued. They are also submitted to flammability tests and finally chemical testing to ensure they contain no hazardous substances in concentrations that could be harmful.

The second reason for third-party testing is to ensure that the product can be used as intended. The tests would give manufacturers proof for the claims made about the product. Parts and materials are, in some cases, tweaked until satisfactory. The final product sample then becomes the “golden” sample against which all products made in mass production are assessed. The goal is to ensure the imported product meets legal compliance and customer satisfaction.

The tests would give manufacturers proof for the claims made about the product. Parts and materials are, in some cases, tweaked until satisfactory. The final product sample then becomes the “golden” sample against which all products made in mass production are assessed. The goal is to ensure the imported product meets legal compliance and customer satisfaction.

3. Outlining requirements in a QC checklist

Even with a “golden” sample, it is useful and adopted by a vast majority of brands to explicitly state quality requirements in a quality checklist. The QC checklist, or inspection criteria sheet (ICS) give inspection criteria to QC staff. These checklists address a few key areas:

- Product requirements, including color, dimensions, and materials

- Packaging requirements

- On-site tests and checks

- Defects classifications

The checklist ensures that the quality requirements are clear and agreed upon. Suppliers would know for certain what is expected from them.

All these steps come together to ensure that defects are prevented even before production begins. In the next article, we will cover what is done during the production process to minimize the occurrence of defective products at the end of production.

Article referenced from Asia Quality Focus’ e-book How Experienced Importers Limit Product Defects in 3 Stages.