- The safety standards concerning global toy imports and sales are extremely strict. Have you ever seen what a test on a toy looks like?

- In the European Union, an estimated 81,000 children each year are injured because of toys.

- In the European Union, toys remain the single largest category of non-food products identified as unsafe, accounting for 26% of more than 2000 unsafe product identified in 2016.

Due to their intended audience, children’s toys must comply with complex and strict regulations before they can be imported and sold in most global markets.

In the European Union, the multifaceted standard that regulates the safety of all toys is called EN 71, and it outlines the various tests that must be performed to comply with European directives.

Who are the EN 71 standards protecting? What types of risks is it protecting against?

The EN-71 standards apply to toys that are intended for children up to the age of fourteen. EN 71 has specifics sections covering the suitability of toys for various ages, including a range of notifications for toys that are unsuitable for children under three years old.

The legislation is divided into several sections covering various aspects of safety, but, for the majority of toys, there are three pertinent parts.

– EN 71-1: Mechanical and Physical Properties includes testing to avoid the detachment of ‘small parts’ that could cause choking hazards, and other testing to detect sharp points, and cutting edges that could lead to injuries.

– EN 71-2: Flammability assesses & analyzes the flames spreading speed on a toy to make sure the child has enough time to move away from it if the toy should catch fire.

– EN 71-3: Migration of Certain Elements, simulates the digestion of a child that may have swallowed a toy in order to analyze if heavy metals/materials can be transferred from toy to the body (19 heavy metals each with a specific limit value.)

In this article, we will focus on the EN 71-1: Mechanical and Physical Properties section, and examine through a video and explanations, some of the common tests used by laboratory technicians to ensure toys comply with this standard.

Mechanical and Physical Properties – Identifying potential choking hazards and injuries

The safety standard related to the mechanical and physical properties comprises over 30 safety tests. This includes toy structural integrity, whether surfaces or edges will cause lacerations, and the dimensions of a toy in relation to potential choking hazards. The following video will display four of the main tests that make up this section.

Objective A: identifying choking hazard risks

While the Canadian law is a bit different from the European, in 2017, CBC News analyzed the details of every toy recall in Canada over the past decade and found that of the 423 recalls between 2007 and 2017, which affected 11 million toys, small parts that break off or are easily swallowed were the most common safety hazard, resulting in 230 out of the 423 recalls.

Common tests:

- Tension Test – The tension test evaluates whether small parts snap off the main body of the toy when tension is applied and create a choking hazard. In the video, we see that the laboratory technician pulls the toy with a force equivalent to a child’s strength. In this particular case the test failed since a small part that could cause a choking hazard detached.

- Impact Test – This test ensures that no small parts, which could cause choking, detach from the main body of the toy when a shock is applied to it. In the video, we see a weight dropped on a small toy to see whether any parts detach and could cause a choking hazard. In this case the test was passed because the toy stayed intact.

Objective B: avoiding injuries

Several of the tests that make up the EN 71-1 standard are designed to evaluate the possibility of the toy causing physical injuries, such as lacerations or puncture wounds.

Common tests:

- Cutting Edge Test – In this evaluation, a toy is placed against a rotating rod covered with an adhesive paper. If the paper is torn, then the edge is identified as cutting. In the video, one side of a small car was tested. During the test, the paper on the rotating rod wasn’t torn and the test was therefore passed.

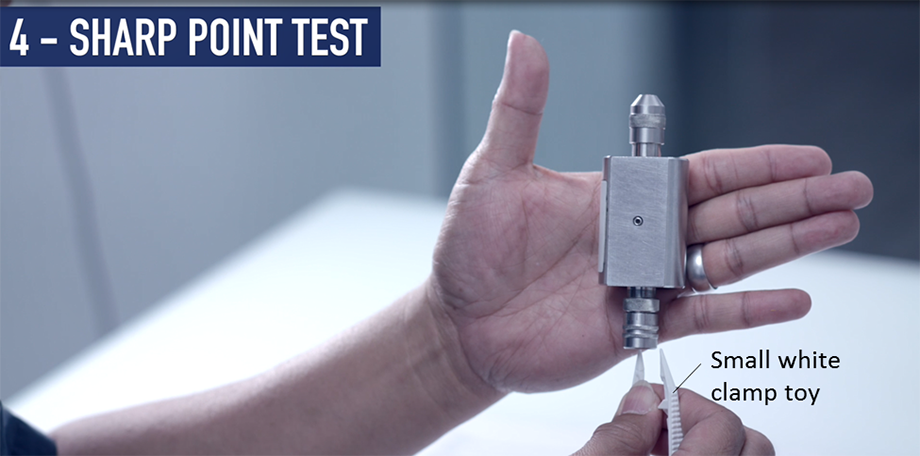

- Sharp Point Test – The sharp point test is used to check whether the pointed areas of toys are sharp enough to hurt children as they play with them. If the point of a toy is sharp enough to pose a risk of injury, the device detects it and visually alerts the technician by lighting a red LED. The video clearly displays the red LED turning on to notify the lab technician that this toy isn’t safe.

The Price of Failure – What happens when a toy doesn’t pass the tests?

If a toy fails to meet the required safety standards, it will immediately be withdrawn from sale or prevented from being sold in the first place. The producer of that toy faces the possibility of being found guilty of a criminal offense, which can result in fines or even imprisonment.

It is for this crucial reason that lab technicians must ensure they follow the EN 71 directive, and carefully perform the tests as outlined above. Not only are they keeping children safe from the dangers of hazardous products, but they are also indirectly encouraging toy producers to do their utmost to regulate their manufacturing processes and avoid prosecution.

Another important consideration for manufacturers is that the entire EN 71 directive is continually assessed and can frequently be updated. For example, in 2013, changes were made to include a broader range of toy types and revamp the number of restricted materials. For instance, the testing methods were revised in the 2014 to clarify a test method. It’s the responsibility of the brand or importer to ensure that manufacturers are adhering to the latest version of relevant safety standards.